Waste

2030 Waste Goals and Our Progress to Date

In 2021, we established new waste goals to reduce landfill waste, address plastic waste from our operations and support integration of sustainability into the designs of our products.

Zero waste to landfill from routine operations

In 2022, 15 out of Lilly’s 28 facilities achieved the zero-landfill target, resulting in 1.7% of our waste from routine operations being sent to landfill. This was an increase from 2021, which was driven by an operational issue on one of our internal waste management processes and an outage at one of the external waste-to-energy facilities that Lilly utilizes. We do not anticipate these issues to impact our long-term goal performance.

100% of plastic waste repurposed for beneficial use, with at least 90% recycled or reused

In 2022, Lilly estimates that we were able to repurpose 98.0% of plastic waste for beneficial use (reuse/recycle/waste-to-energy), primarily driven by recycling of plastics from our manufacturing processes and incoming packaging material. This is a slight increase over 97.7% repurposing in 2021. Of this plastic waste, 89.6% was recycled or reused, bringing us close to our 90% goal.

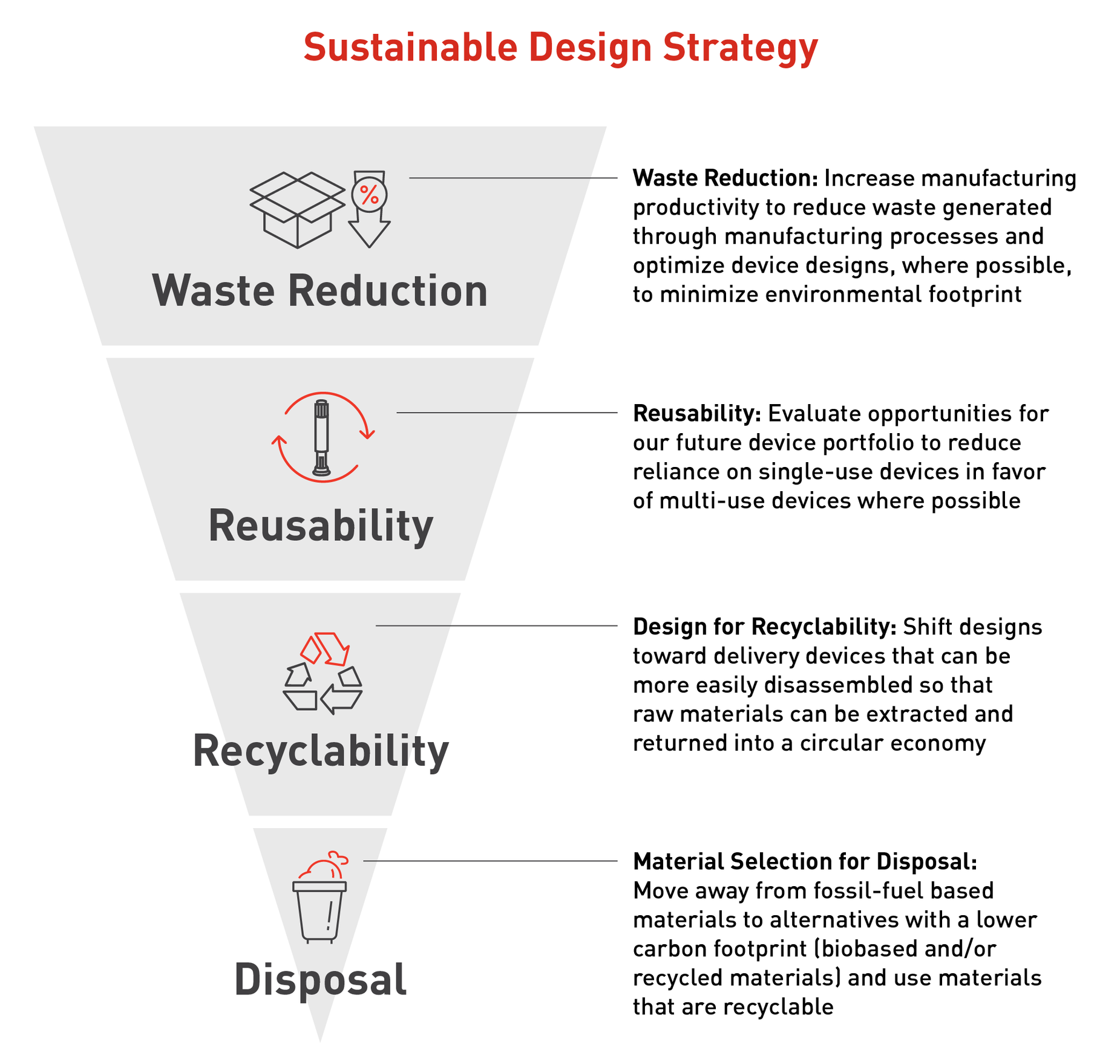

Integrating sustainability-focused design principles into product and packaging design processes

We continue to build on efforts to incorporate sustainability into the lifecycle of our products, delivery devices and packaging with waste reduction in mind. We strive to develop products that are inclusive, trustworthy and sustainable. Learn more about our approach to integrating sustainability into our product and packaging designs.

Plastic Waste Reduction Efforts

We are focused on minimizing our plastic waste footprint. To do this, we reduce the generation of plastic waste where possible, identify where recycled plastic materials are suitable for use in our processes and maximize the reuse and recycling of plastic waste. When reduction, reuse and recycling are not viable, we send plastic waste to a facility that converts waste into energy.

In 2021, Lilly began developing processes for measuring and reporting plastic waste. We use both quantitative and qualitative measurement systems. These systems allow us to estimate our current progress relative to our plastic waste goals, and we strive to improve these measurement systems over time.

As noted above, we estimated we were able to repurpose 98.0% of our plastic waste for beneficial use (reuse/recycle/waste to energy) in 2022, primarily driven by recycling of plastics from our manufacturing processes and incoming packaging material. Of our total plastic waste, approximately 89.6% was recycled or reused. While these numbers are close to our established plastic waste goals, we anticipate that it will take significant efforts – such as new technologies and innovative external capacity -- to achieve 100% beneficial use and at least 90% reused or recycled.

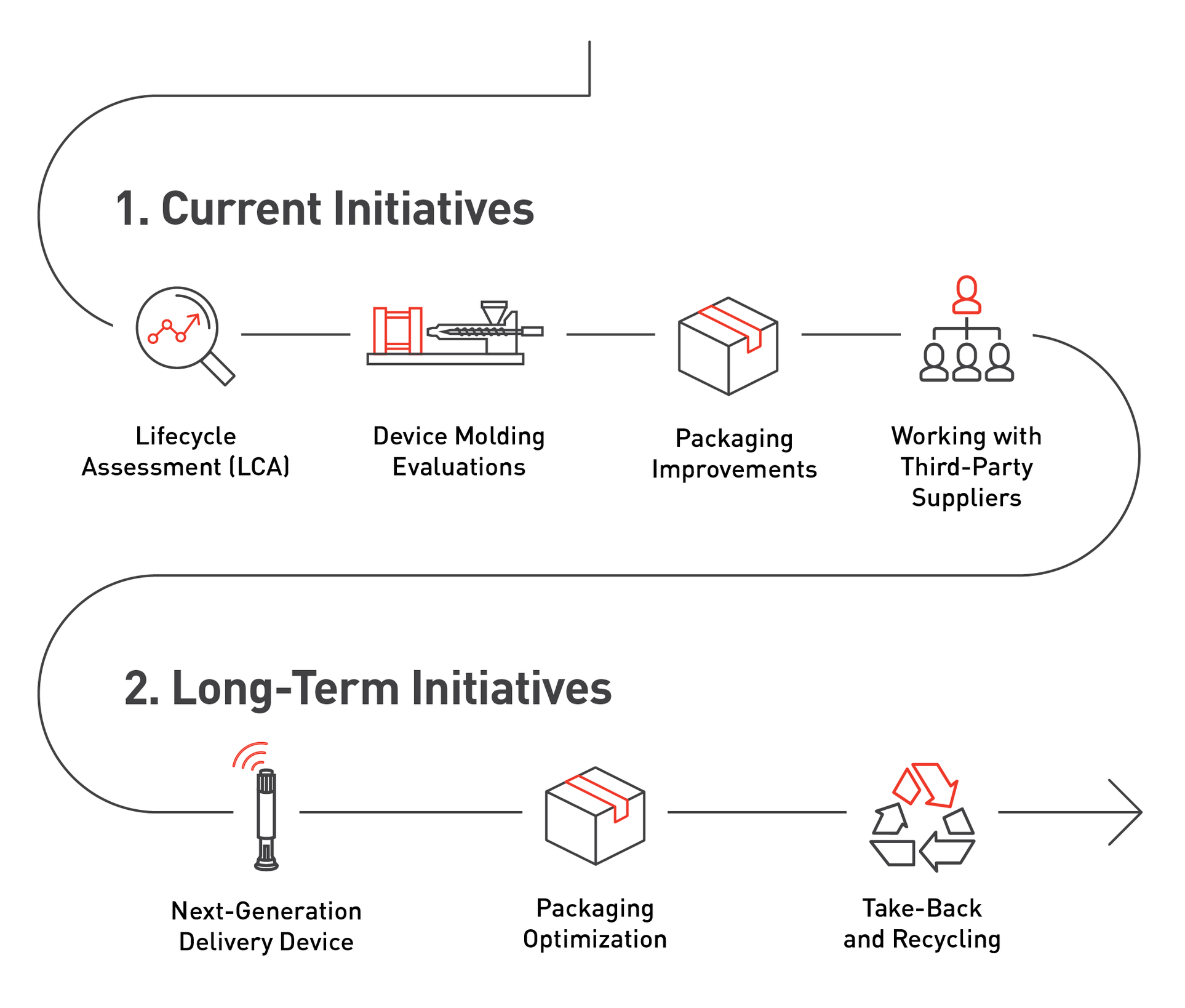

Integrating Sustainability into Our Product and Packaging Design Processes

To support our 2030 waste goals, we continue to build on efforts to incorporate sustainability into the lifecycle of our products, delivery devices and packaging, with waste reduction in mind. Our goal is to integrate sustainability-focused design principles into future product and packaging design processes, while identifying and evaluating opportunities to enhance our current portfolio. We aspire to develop products that are inclusive, trustworthy and sustainable.

Inclusive

We strive to design intuitive experiences that are inclusive of the unique capabilities and changing conditions of people around the world and that meet their diverse abilities and needs.

Trustworthy

We demonstrate care and compassion for people and aim to create devices and packaging that are consistent, reliable and easy to learn and use across all touchpoints.

Sustainable

We strive to design our therapies, devices, packaging and experiences for longevity and minimal environmental impact.

We aim to make our products more sustainable without sacrificing safety, user experience, or patient outcomes. We strive to position our products at the top of our “reduce, reuse, recycle” waste hierarchy, and design for recyclability while also minimizing medical waste and electronic waste. We are investing to research and identify renewable/bio-based materials to make our future packaging and devices more sustainable and exploring collaborations and partnerships with our key materials suppliers to evaluate the feasibility for improving the sustainability of existing devices.

Lilly has developed a Design for Sustainability Guidebook to support design of our next generation of delivery devices to meet Lilly’s environmental goals. The guidebook is utilized internally to provide insights into sustainability approaches in the areas of device and secondary packaging design, materials and recycling. It aims to increase knowledge in this space and explores best practices when designing our devices and packaging in a regulated environment.

Visit our Product Stewardship page to learn more about our approach to sustainability throughout product life-cycles.

Waste Performance Data

Total Waste Generation (1)

|

2019

|

2020

|

2021

|

2022

|

|---|---|---|---|---|

|

Total Waste Generation (metric tonnes)

|

2019:

140,000

|

2020:

130,000

|

2021:

118,000

|

2022:

123,000

|

|

Non-Hazardous Waste (metric tonnes)

|

2019:

120,000

|

2020:

110,000

|

2021:

98,000

|

2022:

101,000

|

|

Hazardous Waste Generation (metric tonnes)

|

2019:

19,000

|

2020:

20,000

|

2021:

20,000

|

2022:

22,000

|

Total Waste Disposition (1)

|

2019

|

2020

|

2021

|

2022

|

|---|---|---|---|---|

|

Beneficial Use (includes recycled, reused and waste-to-energy)

|

2019:

130,000

|

2020:

120,000

|

2021:

108,000

|

2022:

111,000

|

|

Treated (includes combustion without energy recovery) (metric tonnes)

|

2019:

7,000

|

2020:

7,300

|

2021:

7,100

|

2022:

8,000

|

|

Landfilled (metric tonnes)

|

2019:

5,000

|

2020:

2,700

|

2021:

2,300

|

2022:

4,000

|

Waste Metrics for Goals (1)

|

2019

|

2020

|

2021

|

2022

|

|---|---|---|---|---|

|

Waste Generated from Routine Operations (metric tonnes)

|

2019:

Not previously reported

|

2020:

Not previously reported

|

2021:

107,000

|

2022:

110,600

|

|

Waste to Landfill (metric tonnes)

|

2019:

Not previously reported

|

2020:

Not previously reported

|

2021:

600

|

2022:

1,900

|

|

Plastic Waste from Routine Operations (metric tonnes)

|

2019:

Not previously reported

|

2020:

Not previously reported

|

2021:

8,600

|

2022:

12,000

|

|

Plastic Waste Repurposed for Beneficial Use (includes recycled, reused and waste-to-energy) (metric tonnes)

|

2019:

Not previously reported

|

2020:

Not previously reported

|

2021:

8,400

|

2022:

11,800

|

|

Plastic Waste Recycled or Reused (metric tonnes)

|

2019:

Not previously reported

|

2020:

Not previously reported

|

2021:

7,600

|

2022:

10,800

|

Waste Goal Performance (2)

|

2030

|

2022 Performance

|

|---|---|---|

|

Percent of Waste from Routine Operations Sent to Landfill3

|

2030:

Zero (less than 0.5%)

|

2022 Performance:

1.7%

|

|

Percent of Routine Plastic Waste Repurposed for Beneficial Use

|

2030:

100%

|

2022 Performance:

98.0%

|

|

Percent of Routine Plastic Waste Recycled or Reused

|

2030:

Greater than or equal to 90%

|

2022 Performance:

89.6%

|

|

Integrate Sustainability-Focused Design Principles into Our Products and Packaging

|

2030:

N/A

|

2022 Performance:

On Track

|

Footnotes

Note: Some segments do not add up to totals due to rounding.

Note: Bureau Veritas was engaged by Eli Lilly and Company to provide limited assurance in relation to specified 2022 environmental performance data presented.

Total waste includes all waste generated from Lilly facilities, routine waste and non-routine waste. Non-routine waste is defined in footnote 2.

Waste goals exclude waste from the following categories: non-routine construction and demolition debris (e.g., building construction or demolition); uncontaminated soil, rock, concrete, bricks, etc., used for clean fill; waste generated as a result of remediation of surface or underground areas (e.g., soil, rock, water and personal protective equipment); vegetation (e.g., landscaping debris), wastewater that is conveyed offsite through piping (i.e., not shipped offsite in container or tanker) for treatment or discharge; and biosolids or other residue from wastewater or stormwater collection and treatment.

For the purpose of our landfill goal, “zero landfill” is defined as elimination, reuse, incineration, reclamation or recycling to the point that routine waste as generated will no longer be placed in a landfill. A site may achieve “zero landfill” status if less than 0.5% of its generated routine waste is sent directly to landfill. Lilly will meet “zero landfill” status if less than 0.5% of Lilly’s routine waste as generated is sent directly to landfill.

View Lilly’s environmental data from 2020, including our previous goals and progress through 2020. Additional historical data are available in our reporting archives.

Explore our Environmental Goals and Progress

See important information about our ESG report.